cast iron pipe relining

Northern Beaches

All our relined cast-iron pipes have guaranteed full service life. Enjoy the same advantage now and you’ll never experience drains problem again.

The Best Way to Rehabilitate Old Cast Iron Sewer Lines- Pipe Relining Services in Northern Beaches

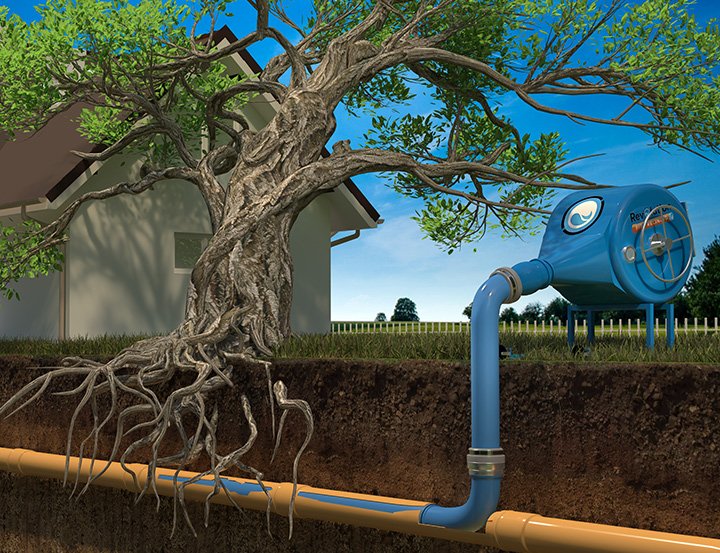

Did you know that houses built before the 1970s are at risk of sewer system failures? Back then, cast iron pipes were the standard for plumbing due to their durability. However, new materials and technology have since surpassed them in longevity and ease of maintenance. For pre-1970s homes relying on cast iron pipes, the problem is their pipes are nearing the end of their lifespan, potentially compromising the sewer system’s functionality.

The issue with cast iron pipes is their expected 100-year lifespan, which can be cut short, even within 30 years, due to corrosion, especially in salt-rich soil and underground moisture. If your property was built before the mid-1980s, corrosion can lead to holes, blockages, and leaks in cast iron sewer pipes, sometimes starting underground. To avoid costly damage to your plumbing system, it’s best to consider the expert services from a reputable pipe relining contractor. They can address sewer line issues with cast iron pipe relining solutions in Northern Beaches before they become severe. When it comes to plumbing woes, remember that prevention is key.

Step-by-Step Cast Iron Pipe Relining Process

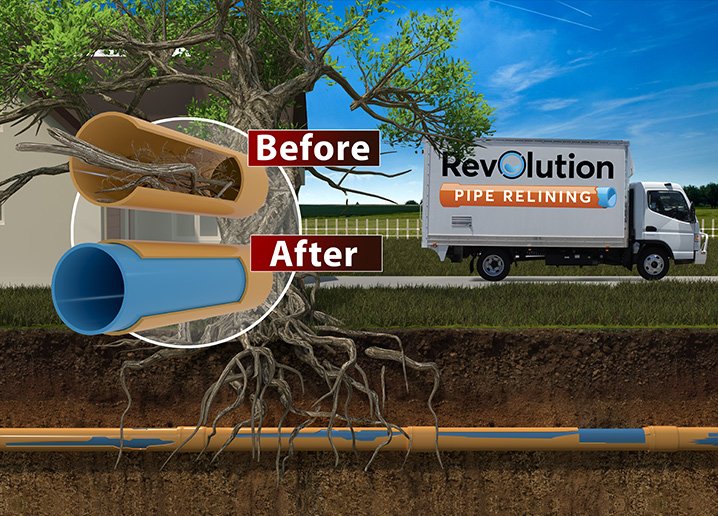

Cast iron pipe relining is a highly effective method for rehabilitating aging or damaged pipes. It provides a cost-efficient and durable solution, extending the lifespan of the pipe and minimizing the need for costly and disruptive pipe replacement. Properly executed, this process ensures that the rehabilitated pipe functions efficiently and remains corrosion-resistant for years to come.

Step 1: CCTV Pipe Drain Inspection and Assessment

The cast iron pipe relining process begins with a thorough inspection and assessment of the existing pipe. This is crucial to determine the extent of damage, corrosion, and the overall condition of the pipe. A specialized camera is used to conduct a video inspection, allowing professionals to pinpoint problem areas and measure the length of lining material needed.

Step 2: Thorough Cleaning

Before embarking on the relining journey, it’s paramount to begin with a clean slate. Existing cast iron pipes must undergo a meticulous cleansing process. The presence of debris, scale, rust, and other unwelcome obstructions can significantly impede the relining procedure and compromise the ultimate durability of the lining. The go-to technique for this critical task is hydro-jetting, where high-pressure water serves as the dynamic force capable of dislodging and eradicating these contaminants. Through hydro-jetting, the inner surface of the pipe is not only purged of hindrances but also prepped for the transformative relining process.

Step 3: Precise Liner Preparation

The linchpin of cast iron pipe relining lies in the liner itself—an epoxy resin-saturated marvel. To ensure a flawless fit within the pipe, this liner is expertly measured and cut to the exact required length. Precision here is paramount. Moreover, the epoxy resin is meticulously prepared, guaranteeing its seamless saturation of the liner material. This harmonious pairing of liner and resin forms the bedrock upon which the rejuvenation of the cast iron pipe depends.

Step 4: Liner Integration

With the liner meticulously prepared and saturated with epoxy resin, it’s time for integration. The epoxy resin-saturated liner is deftly inserted into the previously cleansed cast iron pipe. In some instances, an internal balloon or bladder may be judiciously employed to facilitate this insertion process. Methodically, the liner makes its journey through the entire length of the pipe, adhering closely to the inner walls. It’s this meticulous integration that sets the stage for the cast iron pipe’s remarkable transformation, delivering renewed strength and resilience.

Step 5: Curing Process

Following the meticulous placement of the liner, the epoxy resin embarks on a vital process of curing. This crucial step usually entails the application of heat or ultraviolet (UV) light, serving as the catalyst for the resin’s hardening process. As this transformation unfolds, the epoxy material forges an unyielding and enduring connection with the inner lining of the preexisting pipe. This resulting bond is nothing short of remarkable, as it manifests into a flawless barrier. This barrier not only reinstates the pipe’s structural integrity but also fortifies it against the relentless forces of corrosion.

Step 6: Final Inspection

After the curing process is complete, a final video inspection is conducted to verify the successful installation of the pipe liner. This inspection ensures that there are no defects, wrinkles, or areas where the liner did not adhere correctly. It also confirms that the relined pipe is free from any blockages or damage that might have been missed during the initial assessment.

Step 7: Reconnection

Once the cast iron pipe relining is confirmed to be successful and free from defects, it is ready for reconnection to the plumbing system. Any necessary connections or modifications are made to integrate the newly relined pipe into the existing system seamlessly.

Unmatched Cast Iron Pipe Relining Solutions in Northern Beaches

At Revolution Pipe Relining, we recognize that home pipe relining can be a significant and unexpected expense. That’s why we are dedicated to delivering top-notch, cost-effective pipe relining solutions in Northern Beaches that get it right the first time. With over 40 years of expertise in pipe repair, our skilled contractors will swiftly and efficiently address your plumbing issues, ensuring they don’t break the bank.

We pride ourselves not only on the quality of our work but also on the preservation of your property’s integrity. When our job is complete, your property will be restored to its original condition. Whether it’s pavers, concrete, or grass that needs replacement, we’ll ensure your utmost satisfaction before our trucks depart. If you’re eager to learn more about the cast iron pipe relining process in Northern Beaches or would like a no-obligation quote, don’t hesitate to call our direct line on 1300 844 353 today. Experience exceptional service that transforms your plumbing problems into peace of mind.

This video will show you our comprehensive pipe relining process. Take notice of how smooth the relined surface is. This gives proof that your old pipe can be restored to its full-functional condition after relining.

FREE Annual CCTV Inspection to monitor our work.

LIFETIME GUARANTEE On Relined Sections

Products Made In Germany & the UK

We Will Beat Any Equivalent Quote

100% Australian WaterMark Approved

warning signs of a damaged sewer pipe

Damages underneath the ground are not always easy to tell because they’re not visible. They could be hiding behind your walls on creeping in spaces like the basement or your driveway. Knowing the warning signs to look out for will help you predict when to call the plumbers to address it urgently.

• Discolouration – Brown or yellow coloured water coming out of your pipes indicates a buildup of corrosion or rust which cast iron pipes are especially vulnerable. Discolouration can also cause brown stains on your sink. Discoloured water is the most visible sign that you urgently need to replace or reline your cast iron pipes.

• Leaks – Leaks are also visible signs of damaged cast iron pipes. If the leaks happen in multiple areas in your home and continuously persist even after repeated cleaning, you need to make urgent contact with the expert.

• Slow Drain – When you experience slow flow or backing up, there’s a big possibility that your cast iron pipe has totally failed. Cleaning it with a chemical remover is a no-no because chemicals contain sulphuric acid that will create more damage to the pipe.

• Odour – A well-conditioned sewer system should be airtight, but when corrosion starts to happen, leaks are always the result. Leaks on pipes can cause sewer gas to escape that can pose a health hazard in your home.

Cast Iron Pipe Relining Sydney REGIONS We Service Include:

INSIDER FACTS YOU MUST KNOW BEFORE SELECTING A RELINING COMPANY.

click the blue button at the bottom of page to speak with a relining expert!

Leave the guesswork and avoid last-minute surprises before you take action. Our team is just a call away for a CCTV inspection to examine your drains. We can honestly provide you with a quote and a solution plan after the result.