Save your cast iron pipes with Cast Iron Pipe Relining

- Cast iron plumbing, on the record, is extremely dependable, lasting between 80-100 years, and notable for its strength and capability to withstand high pressures. Besides that, cast-iron is also heat-resistant. That is why it has become the standard for plumbing installation in the past. Unfortunately, despite cast iron’s robust aspect, nothing lasts forever for this metal pipe – it has one major flaw. This pipe is inclined to fail due to corrosion, hence, the reason for premature failure. Fortunately, the plumbing industry has changed dramatically, giving birth to new technologies such as Cast Iron Pipe Patch or Cast Iron Pipe Relining Sydney solutions that are far more efficient and cost-effective, to resolve issues with this type of pipe.

What is Cast Iron Pipe Relining?

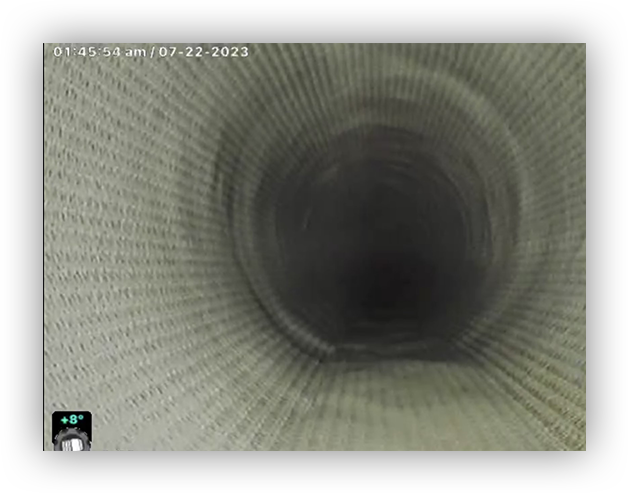

- Similar to the Sewer Pipe Relining process, but this specifically intended for cast iron pipes; the key feature of this method is its ability to restore your failing cast iron pipes into a fully-functional one without the need to dig up the cast iron pipe to replace it, unless, of course, if it has already completely collapsed and your only option is to replace it. In the process, any defects on the pipe are cured inside by sealing the cracks and joints, leaving you with a more seamless surface, and efficient, brand new pipe. Easy ey?

why do cast iron pipes fail?

- Just as with any metal pipe that comes into contact with wastewater and is hidden underground, cast iron pipes have high chances to corrode before its expected end of lifespan; this is specifically because it experiences external factors, such as underground conditions, chemical reactions, that can trigger its loss of structural and physical integrity over time. Keep reading to find out what we are talking about.

- Rusting – Rusting on the interior of the cast iron pipe, for example, is a common problem that happens in cast-iron pipes. It has a double effect which reduces the rate at which water flows on the sewer line. First, rust that forms inside the pipe shrinks the interior width of the pipe as it builds up. Secondly, this rust creates a bumpy surface which constricts the speed at which wastewater can pass through the pipe.

- Corrosion – As a result of what runs through waste lines, hydrogen sulphide gas can form and when it oxidizes, it produces sulfuric acid, which corrodes cast iron pipes. Corrosion is another real danger, detrimental to cast iron pipe health. Over time, wastewater flow will corrode the bottom of the pipe and if left unrepaired will form sectional decay, weaken its structure and eventually lead to complete collapse.

Factors that reduce the lifespan of Cast Iron Pipes

- Many reasons for pipe failure with cast iron pipes come with age and boils down to chemical reactions. One of the most common is the development of a crust of tubercles; this is internal rust that develops inside the pipes, slowing the flow of water and eventually adding to corrosion. Corrosion is apparent in many different ways, from leaks to forming blockages or having pipe sections that rust away. Generally, this is something out of your control because it is a normal part of the pipe’s aging process.

- In some cases, though, uncontested acts on the part of the property owners may speed up the deterioration of cast iron plumbing. Few reasons that plumbing professionals found out are scenarios below.

- Grease – Unlike other biological elements, grease doesn’t break down over time. Grease can come either from food or your beauty soaps. When this is allowed to go down the drain, this can lead to clogs and unpleasant odours from the drain, and in time, cause excessive reduction of pipe’s integrity.

- Drain Chemicals – If you decide to use a chemical for clog remover, try checking for environmentally-friendly, but still effective options. Drain chemicals, when allowed to sit longer in your drains, can produce heat which can only do more harm than good. Environmentally-friendly chemicals do not only help the environment but are also less likely to cause piping problems.

- Acidic Soils – Some soil composition in some areas is inherently acidic. Corrosion of metal pipes in acidic soils is influenced largely by acidity level, that means, too much exposure in ground acid accelerates corrosion rate and can make the pipes fail prematurely.

- Root intrusion – In other cases, you may end up having issues with your cast iron plumbing because of something that is completely out of your control, such as the growth of seeking-moisture tree roots where your pipes run. So it will pay to know if there are trees nearby. If this is your situation, a drain pipe camera inspection will be a good option to consider to inspect your pipes internal condition.

Signs of Pipe Failure

Even the most durable materials are unable to perform at the highest level forever. By now, many of the cast iron sewer pipes that were installed decades ago are starting to reach the end of full-service life and can compromise your entire plumbing system. Therefore, it is essential to understand the common problems these pipes can develop and what are your options to retrieve its condition to full-functionality.

BLOCKED DRAIN

A blocked drain is often the first warning sign of failing pipes. It can be caused by tree roots constricting your sewer pipes or buildups that have been there for a while. Tree roots intrusions are normal scenarios on houses built decades ago. Blocked drain is a sign of corrosion. Allowing this to happen continuously will put your property at high risk for damage. Cast Iron Pipe Relining services Sydney option, is the most ideal solution to fix blocked drain problems. The method will make the relined section of the pipe become seamless and very smooth, allowing water to flow efficiently than before.

LEAKS

Leaks can happen in one area at your property, but, where leaks are repeatedly happening, even after repair means, there’s a concealed problem down the line that requires urgent repair. When leaks are not determined right away, this can result in sky-rocketing water bills. Relining cast iron drain pipes will join together any gaps and leaks on the pipe, thereby restoring it to its full-functional state.

STRANGE SMELLS

A well-conditioned sewer system is airtight, but when corrosion starts to happen, leaks always follow. Leaks on pipes can cause sewer gas to escape, thereby those strange smells. If you start to smell strange odour anywhere in your home, it’s time to call the professionals to address these leaks before it can take a toll to anyone’s health at your property.

discolouration

A brown or yellow coloured water coming out of your pipes is a manifestation of rust and corroded pipe which cast iron pipes are especially susceptible. If you see rust coloured water coming out from multiple taps, it’s a sign for you to contact a plumber.

When it comes to the cast iron pipes overall health, it is difficult to pin down these issues, that’s why when you begin to notice issues with it, or you have an old plumbing system, connect with the Pipe Relining in Sydney experts right away before it will produce more problems that can be costly for you. As you know, like any property repair, pipe relining cost, can also get pricey when it’s already difficult to undertake the repair. That means when the cast iron pipe is severely damaged.