copper Pipe Relining

Sydney CBD

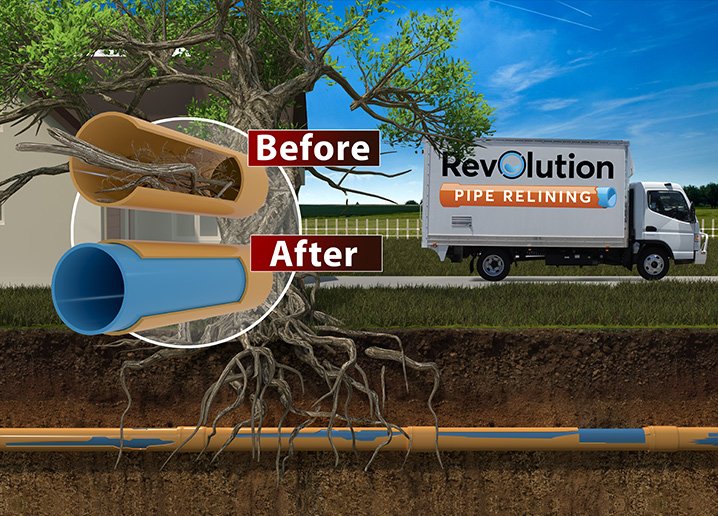

All of our relined sewer copper pipes were restored to full-functional state. So you’ll never have to worry about copper pipe failure anymore.

Copper Pipe Relining in Sydney

A Comprehensive Look at the Copper Pipe Relining Process in Sydney CBD

In the bustling region of Sydney CBD, a revolutionary technique for repairing damaged pipes has gained significant traction. Known as copper pipe relining, this state-of-the-art method stands out as a cost-effective and efficient alternative to the traditional approach of pipe replacement. Gone are the days of massive excavations that disrupt daily life; copper pipe relining offers a faster and far less intrusive solution. Delving deeper into this transformative process, this guide promises to shed light on the intricacies involved.

Whether for a cosy residence or a sprawling commercial establishment, understanding the copper pipe relining procedure ensures you’re well-informed and ready. So, if you ever find yourself in need of rehabilitating your piping system, you’ll know precisely what to expect. Let’s journey together through the step-by-step process of restoring your pipes to their former glory with copper pipe relining.

Understanding the Copper Pipe Relining Process

The copper pipe relining process is a comprehensive and systematic approach to restoring and enhancing the longevity of pipelines. It stands as a testament to modern plumbing techniques that prioritize both functionality and sustainability. Here’s a detailed insight into this transformative procedure:

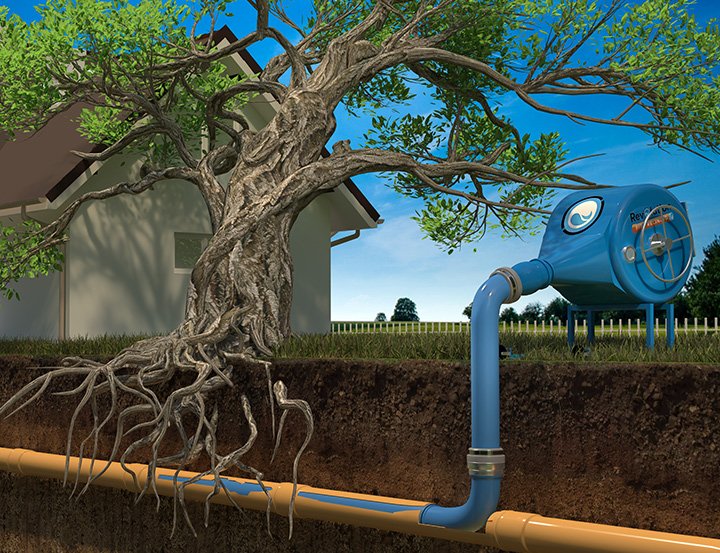

Initiation through CCTV Pipe Inspection

The first step towards repairing an old or damaged copper pipeline is an in-depth inspection. Professionals specializing in copper pipe relining in Sydney CBD utilize advanced CCTV camera systems to delve deep into the pipe’s anatomy. By doing so, they can gauge the level of damage, identify potential issues, and ascertain whether relining is indeed the optimal remedy. This stage serves as the foundation for subsequent actions, aiming to enhance the durability of the plumbing system and shield it from leaks, corrosive damage, and external intrusions.

Pipe Cleaning via Hydro-Jetting

Before introducing the relining material, it’s paramount to ensure the pipes are clean and obstruction-free. This is where hydro-jetting comes into play. With its powerful water pressure, experts can efficiently eliminate any blockages or sediment buildup, creating an ideal environment for the relining process. This thorough cleaning is pivotal for achieving durable and lasting outcomes.

Choosing and Prepping the Relining Materials

Once the pipes are pristine, attention shifts to selecting the most suitable relining materials. Depending on the pipe’s condition, diameter, and specific requirements, specialists opt for materials like premium polyester or fiberglass liners combined with a high-quality two-part epoxy resin. The chosen liner is then drenched in this resin, ensuring it’s primed for a snug fit during the relining phase.

The Inversion and Deployment of Copper Pipe Relining Material

With the resin-coated liner ready, it’s introduced into an inversion tank – a step that’s integral to the relining process. From here, the liner is tactfully inverted and navigated through the pipe, offering a smooth, contiguous repair solution.

Curing the Resin

After positioning the liner, it’s time for the resin to harden and solidify, creating a strong, lasting seal. The duration of this curing phase varies, spanning from mere hours to multiple days, contingent upon specific conditions. To hasten this process, experts might deploy heat or ultraviolet light, ensuring the thorough evaporation of solvents and optimal setting of the resin.

Robotic Precision and Final Scrutiny

Upon the resin’s complete curing, specialists use advanced robotic cutters to meticulously reopen any junctions that got sealed during the process. This step is followed by a concluding CCTV inspection, which certifies the impeccable execution and reliability of the relining procedure.

Depend on Revolution Pipe Relining for Your Copper Pipe Relining Needs

Facing plumbing issues in your property? Don’t let traditional, disruptive methods take a toll on your peace of mind and wallet. Choose Revolution Pipe Relining, the leading name in advanced copper pipe solutions in Sydney CBD. With a commitment to delivering excellence, our seasoned team utilizes state-of-the-art technology to ensure your pipes are restored swiftly and efficiently. We pride ourselves on precision, attention to detail, and utmost care in every project.

Why endure prolonged plumbing issues when a top-tier solution is just a call away? Reach out to Revolution Pipe Relining on 1300 844 353. Experience the future of plumbing rehabilitation, saving both time and money without compromising on quality. With us, your pipes don’t just get fixed; they receive the gold standard treatment they genuinely deserve. Make the smart choice today.

This video will show you the comprehensive pipe relining process we undertake and how amazing your drain will look after relining.

FREE Annual CCTV Inspection to monitor our work.

LIFETIME GUARANTEE On Relined Sections

Products Made In Germany & the UK

We Will Beat Any Equivalent Quote

Interest FreeWatermark 100% Australian watermark approved

sewer pipe problems that copper pipe relining can fix

Although copper pipes are superior in almost all ways, new types of pipe surpass it. It may be relatively resistant to corrosion, but it nevertheless corrodes under certain conditions.

Corrosion and Leaks: There are many types of corrosion, but pitting is most likely to contaminate copper pipes, causing pinhole leaks.

Pinholes and leaks occur when copper oxidizes as it comes in contact with other substances, especially where water has accelerated acidity. Corrosion is hardly detected until leakages start to appear. Therefore, preventative measures significantly contribute, especially if the copper pipes are old enough. As the pipe ages, the possibility of corrosion and pinhole leaks increases.

Relining copper pipes can diminish the chances of these types of piping system to completely fail and decreases its susceptibility to water acidity.

Freezing and bursting: Copper pipes can be susceptible to bursts because of its characteristics as metal. It specifically occurs as a result of extreme temperature exposure. When exposed to cold temperatures, the water inside the pipes can freeze and expand, causing the pipes to burst and break.

Any pipe burst situation is considered to be a plumbing emergency and needs to be inspected and corrected by the experts in copper pipe relining services Sydney. When copper pipes are relined, they are covered with a non-metal coating that will make it invulnerable to bursting and freezing.

Scaling: Scaling inside metal pipes is inevitable and will result in buildups. Buildups gradually decrease the diameter of copper pipes and begin to block the water flow; this eventually reduces the efficiency of your plumbing system.

The buildups of scales inside the copper pipes cause corrosion to occur and should be addressed by pipeline relining Sydney experts to avoid causing more problems in your property. Buildups are eliminated during relining, leaving a smooth pipe surface that increases water flow.

Sydney relining solutions is the ideal fix for all copper pipe problems and even if the pipe has not shown in signs of leakages, bursting, and corrosion yet. Copper pipe relining cost is cheaper than when you wait for it to fail and requires replacement to work as previously.

What are the drawbacks of copper pipes?

With so many advantages, copper also has drawbacks compared to other types of pipes used nowadays. Disadvantages of copper pipes include;

Expensive: The most known restraint of using copper is the cost. The value of copper has dramatically increased in recent years, so today, it will require you to pay around $285 for 100 feet of piping. Therefore, we recommend that as soon as you experience problems with your copper pipes, or as soon as you can afford it, decide to take immediate action to save it from completely failing. Not only it saves you money, but also saves you time from potential future major plumbing works.

Limited flexibility: Copper is flexible as far as metals go, but plastic pipes can bend to fit into almost any space necessary than copper without problems.

BLOCKED DRAINS Sydney REGIONS We Service Include:

INSIDER FACTS YOU MUST KNOW BEFORE SELECTING A RELINING COMPANY.

click the blue button at the bottom of page to speak with a relining expert!

Ignoring copper pipe issues could lead to numerous problems and health risks. Therefore, the best course of action to undertake when you suspect problems with your pipes is to speak with our team for a copper pipe relining solution. We can give you an honest sewer pipe relining cost and the best fix suitable to resolve issues with your copper piping system. Relining can best do its job in restoring copper pipes back to its full functional condition.